A research project to invoke innovation in the development process of industrial machinery

Please note: Due to a non-disclosure agreement with our research partners at Siemens AG the final design and concept of this project cannot be presented to the public. The following images and notes describe the Process and the analysis with the engineers at Siemens’ Dynamowerk in Berlin.

The Dynamowerk is a branch of the Siemens AG located in Berlin focusing on the development and manufacturing of large scale industrial electrical motors. Often tailored to highly specific scenarios and purposes motors of this size are for example used in desalination plants and pumping stations in indoor and outdoor contexts.

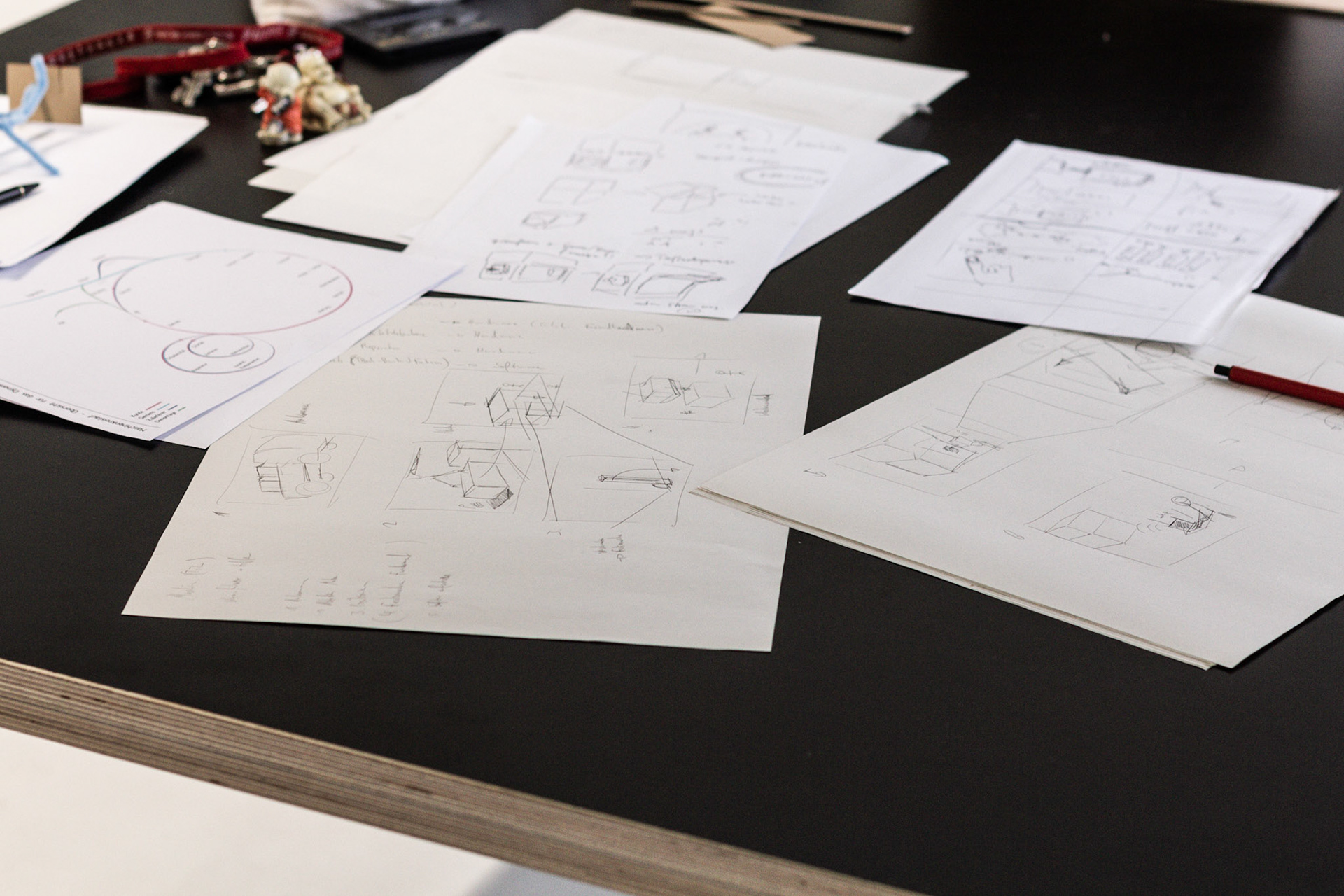

Starting at the thought if (at all) these industrial machines could benefit from design questions quickly shifted towards how innovation and development can be vitalised and enhanced in a heavily regulated industry. A series of interviews and small scale workshops was devised to foster discussion amongst Siemens’ engineers and open the path to possible new patterns of CAD-construction and development.

Credits:

Research Project conducted with the help of the lovely people at Siemens AG | Dynamowerk Berlin

Concept & design by Nina Rossow & Karsten Schuhl

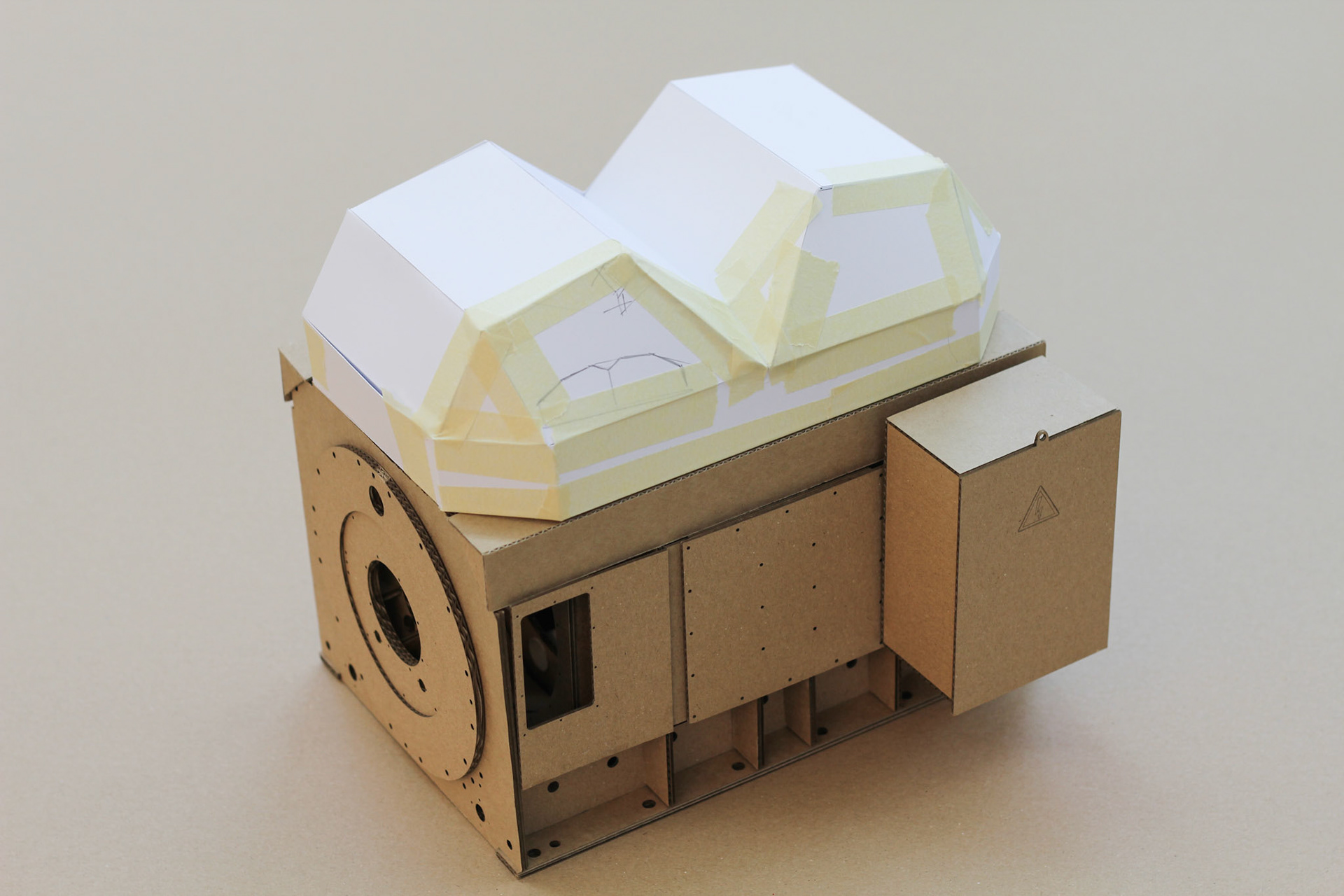

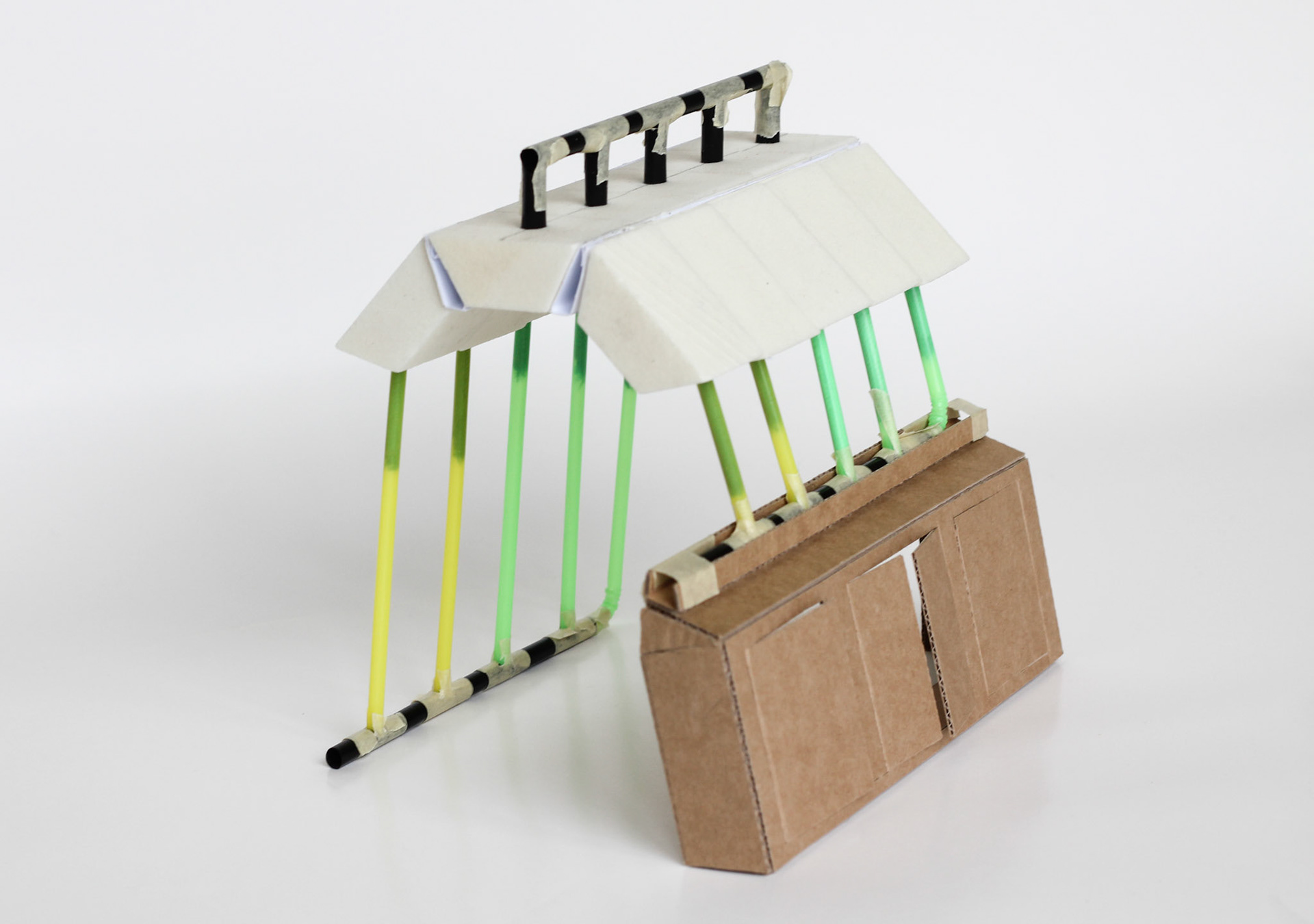

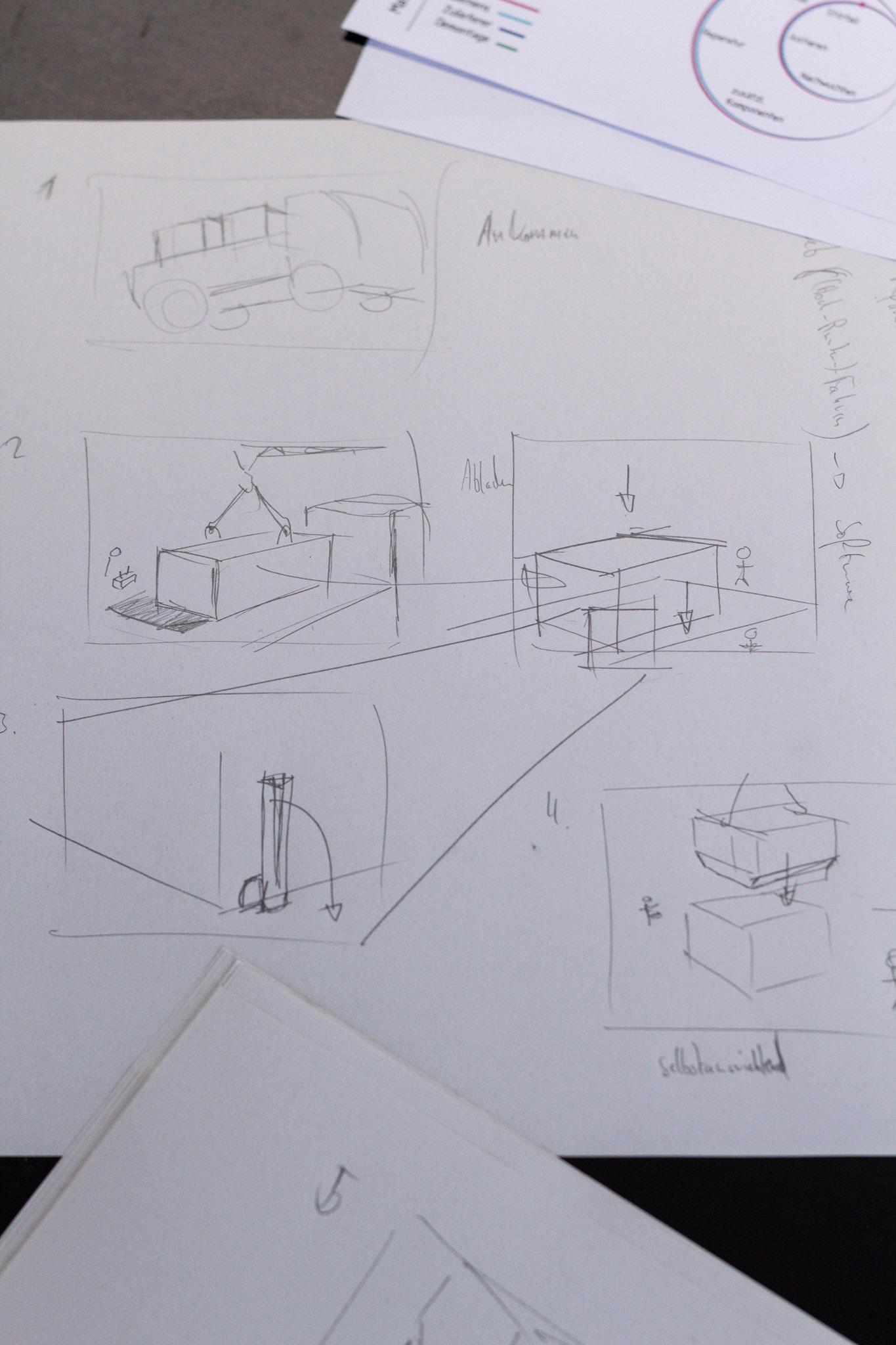

Based on a physical model which was expanded by workshop concepts new abstract solutions were formulated and presented into one final possible design.

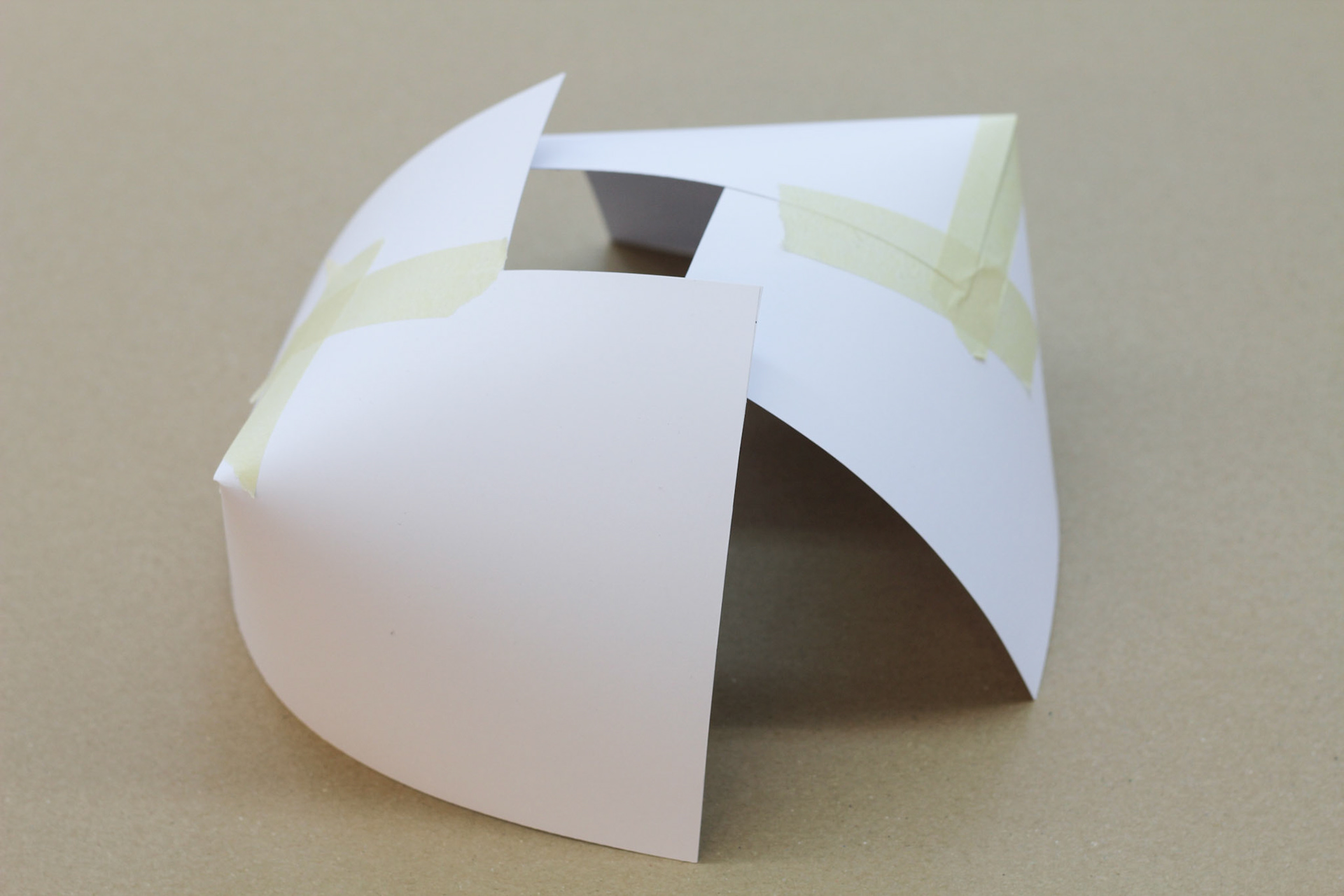

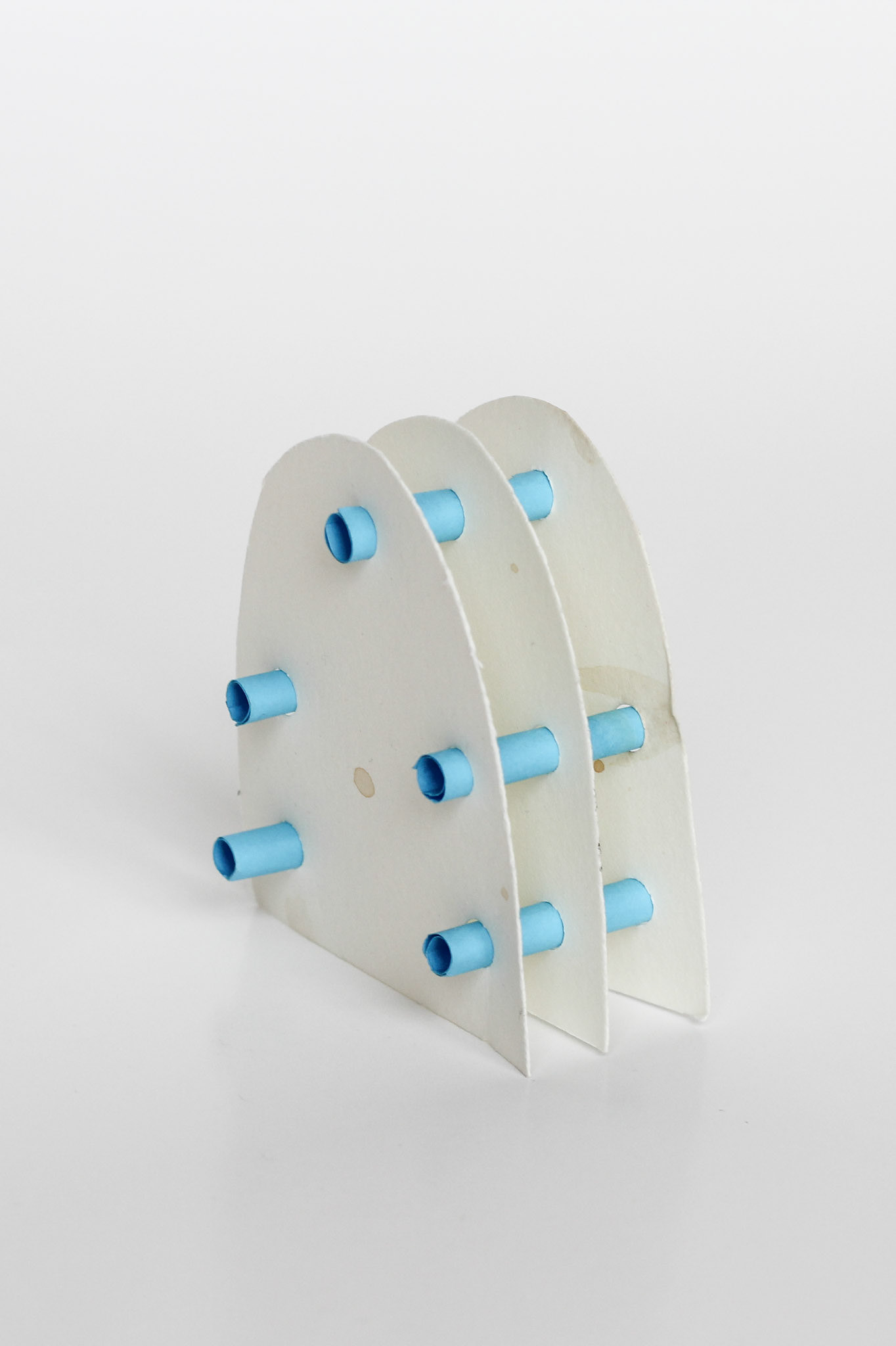

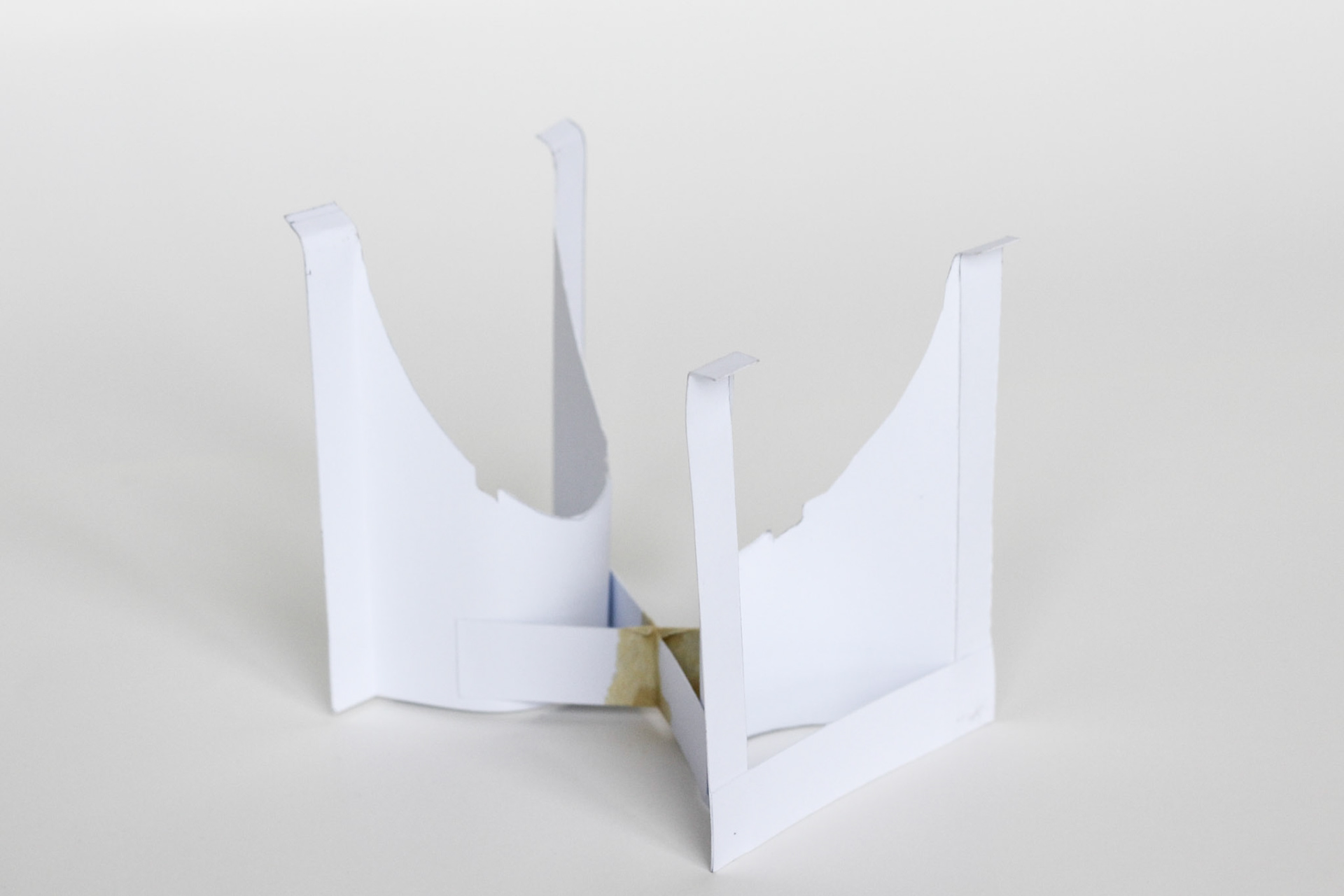

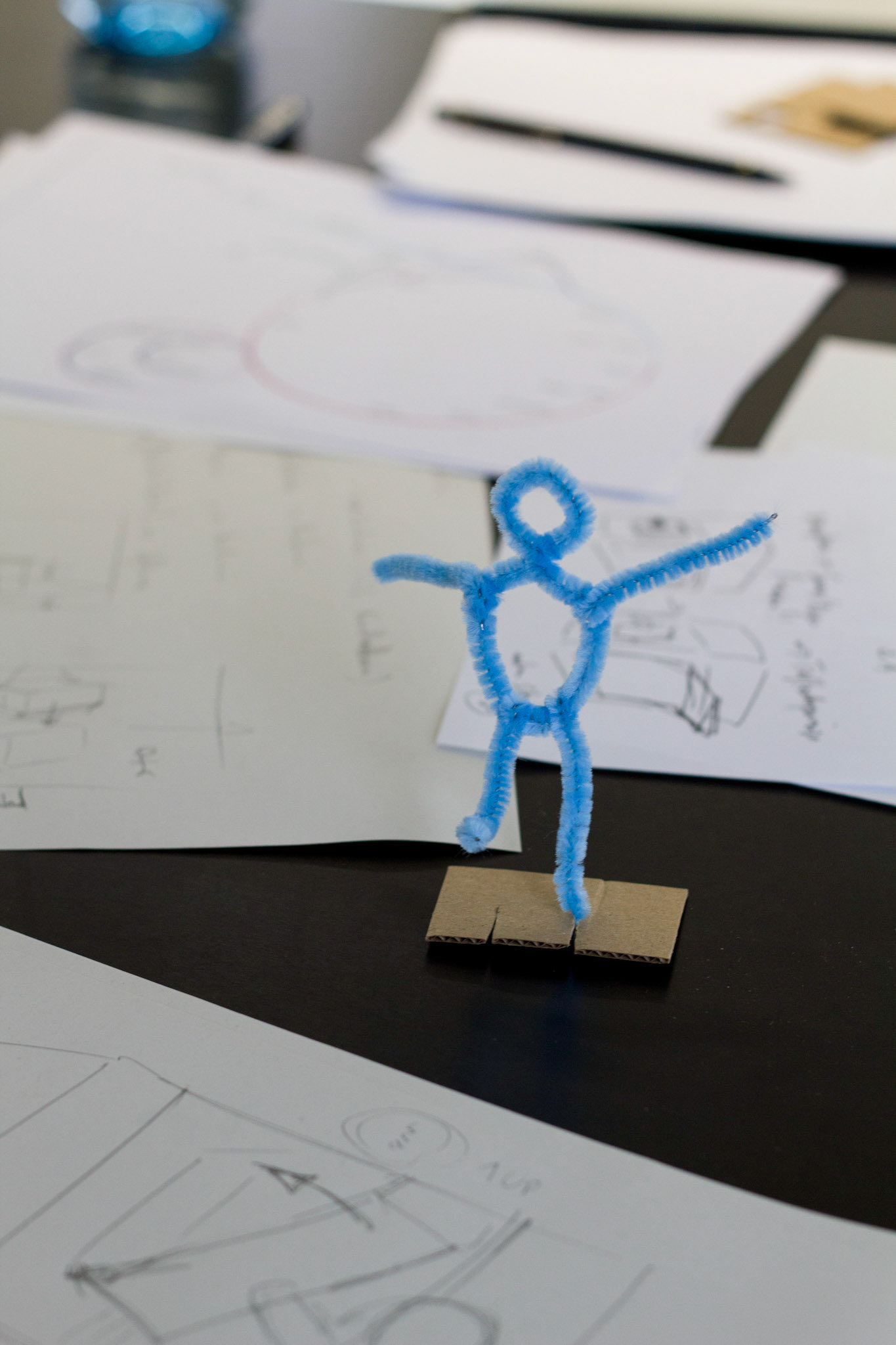

To scale models to ease communication

Quickly made additions to represent for example ventilation

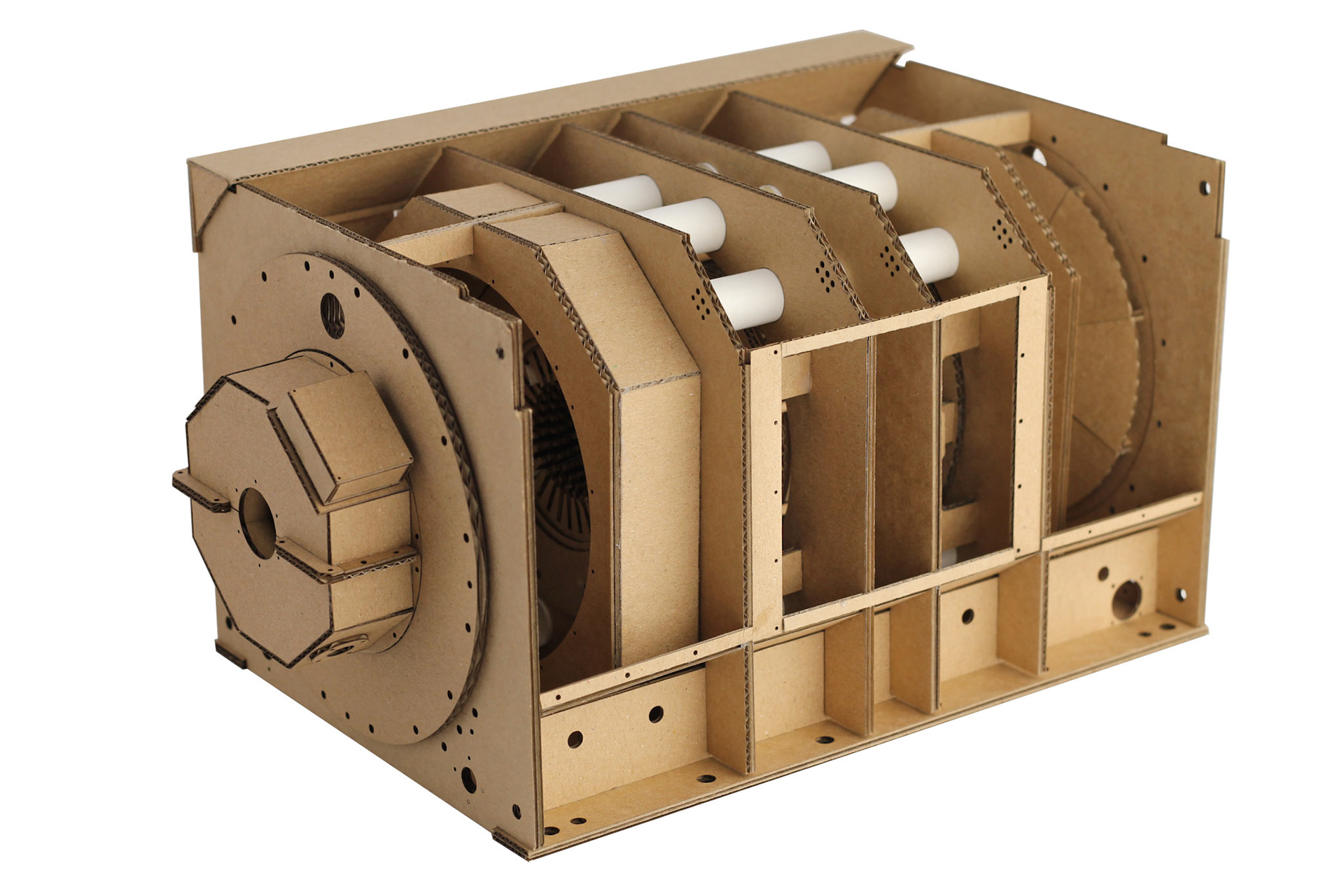

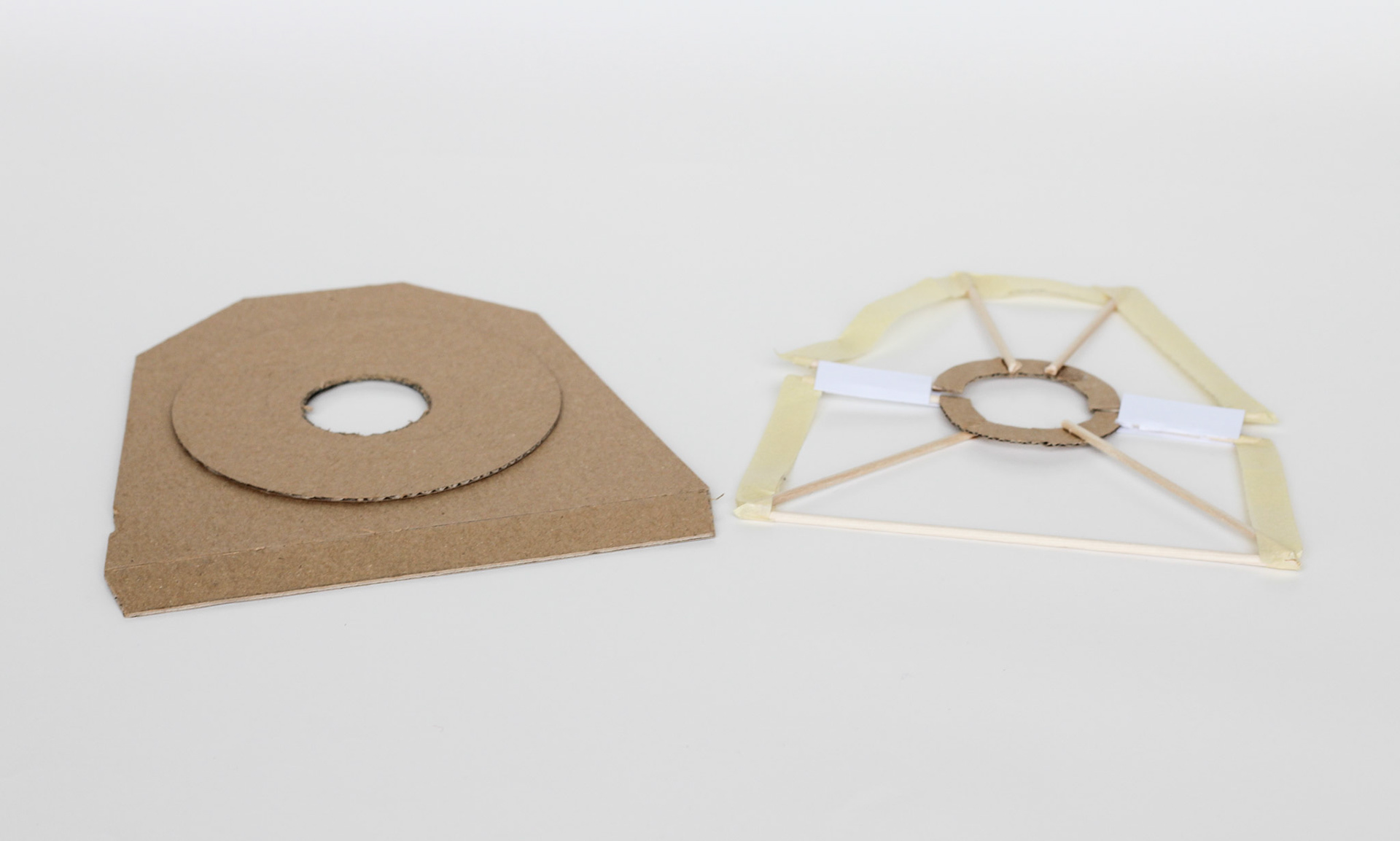

Cardboard model of a state of the art motor to dissect in discussions

A physical model of a specific motor is used to communicate its' basic structure. This was easy to manipulate by everyone involved may it be an engineer, designer or a sales-person.

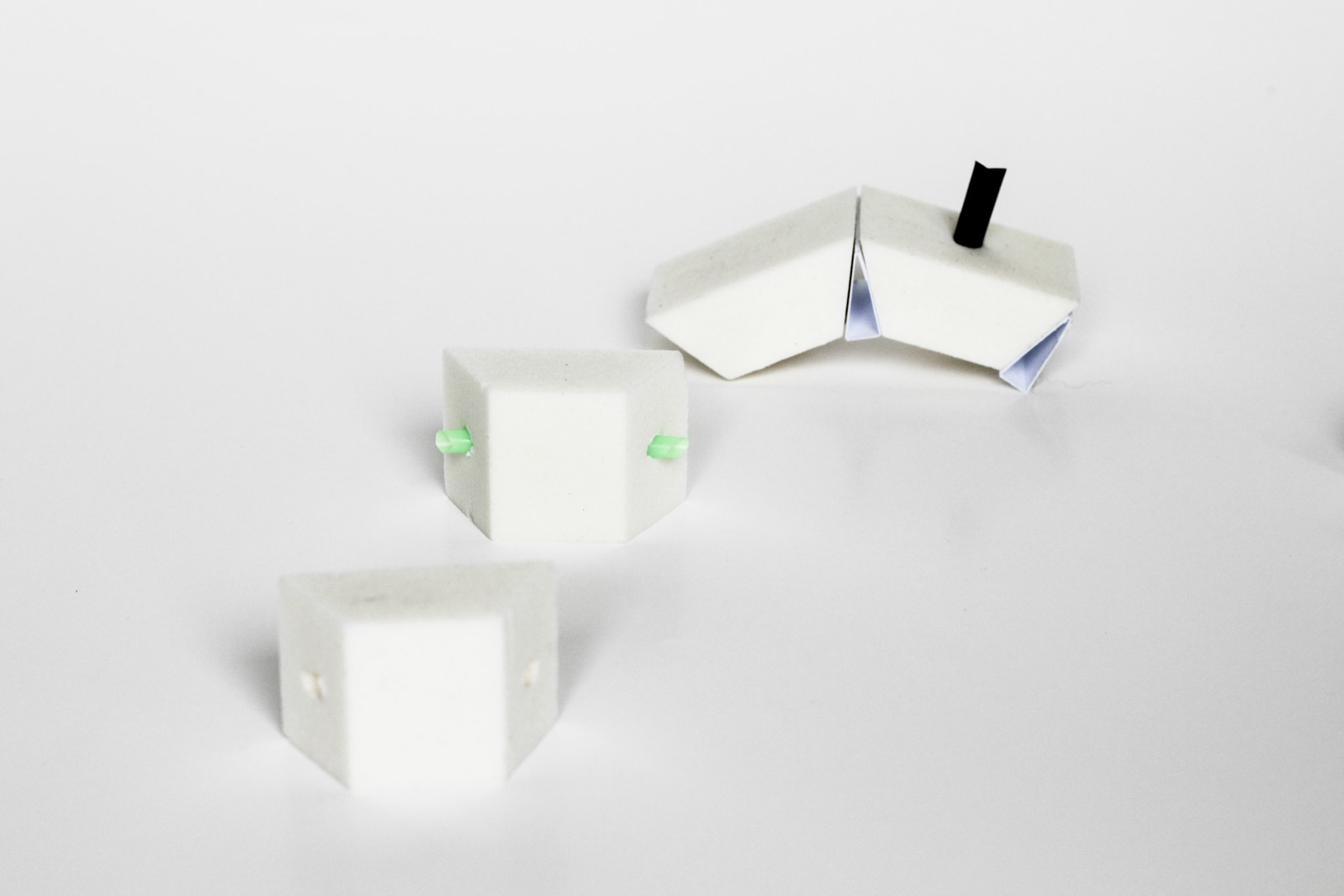

Option: bent sheet metal

Optimized airflow for ventilation

Foam based cooling system to increase surface area

Rigid but mobile bearings

"Sketch" of permeable parts

Adapted tubes for stability

Solid walls vs. membrane structures

Integration of additional components

Skeleton structure

A series of quick structural models with the engineers revealed their wish to explore new opportunities.

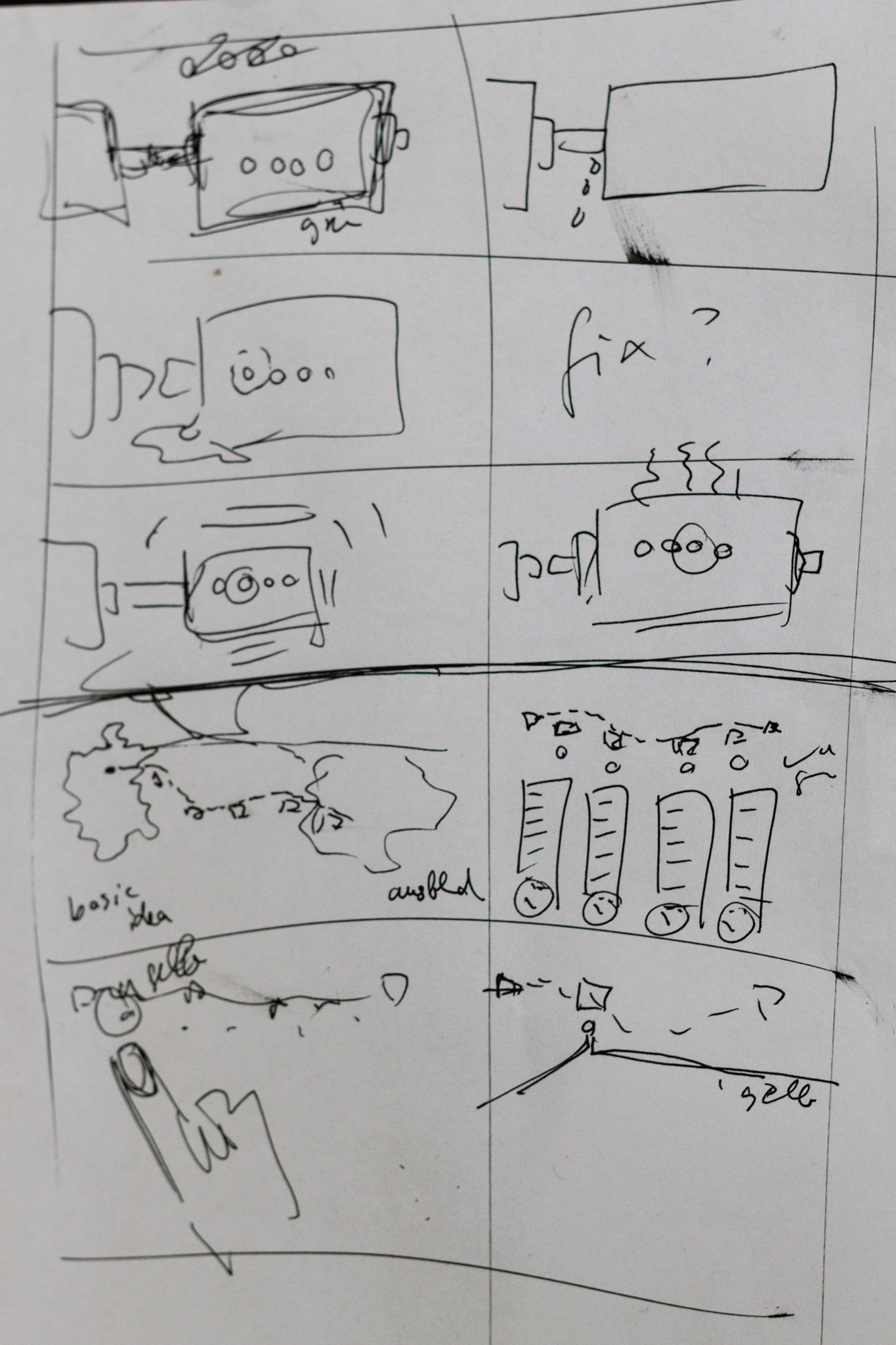

Scenario session to determine challenges

Service scenario

Start-up procedure

Peter - the person on site

Storytelling workshops with engineers, sales- and service-personal helped contextualise the life cycle of the machines and showed ways to incorporate the needs of the other departments into the R&D division.